The Role of Leaf Chains in Automated Packaging Machinery

In the world of automated packaging machinery, leaf chains play a crucial role in ensuring the smooth and efficient operation of the machines. These chains are used to transmit power, motion, and mechanical force in a wide range of applications, from conveyors and elevators to printing presses and packaging machines.

What are Leaf Chains?

Leaf chains are a type of roller chain commonly used in industrial machinery. They consist of a series of interlocking links, each of which has two “leaves” or plates that are connected by pins. The plates are typically made of high-strength steel and are designed to withstand heavy loads and high stress.

How are Leaf Chains Used in Automated Packaging Machinery?

Leaf chains are used in a variety of ways in automated packaging machinery. They are often used as the driving mechanism for conveyors, providing the power and motion needed to move products along the production line. They can also be used in packaging machines themselves, providing the force needed to seal bags or wrap products. In addition, leaf chains are used in elevator and lift applications, providing the lifting force needed to move products from one level to another.

What are the Advantages of Using Leaf Chains in Automated Packaging Machinery?

There are several advantages to using leaf chains in automated packaging machinery. First, they are incredibly strong and durable, capable of withstanding heavy loads and high stress. This makes them ideal for use in industrial applications where reliability and performance are critical. Second, leaf chains are highly customizable, with a wide range of sizes and configurations available to meet the specific needs of each application. Finally, leaf chains are relatively easy to install and maintain, with simple designs that require minimal maintenance or lubrication.

Are There any Disadvantages to Using Leaf Chains?

While there are many advantages to using leaf chains in automated packaging machinery, there are also some potential downsides to consider. First, they can be noisy when in operation, which may be a concern in some applications. Second, leaf chains can be more expensive than other types of roller chains, particularly when customized sizes are needed. Finally, leaf chains may require more frequent maintenance than other types of chains, particularly in high-stress applications.

What is the Future of Leaf Chains in Automated Packaging Machinery?

As the demand for automated packaging machinery continues to grow, the role of leaf chains is likely to become even more important. Manufacturers are constantly seeking new ways to improve the efficiency and performance of their machines, and leaf chains are an important part of that equation. With their strength, durability, and customizability, leaf chains are poised to play a crucial role in the future of automated packaging machinery.

What are Table Top Chains?

Table top chains are another type of chain commonly used in automated packaging machinery. As the name suggests, these chains have a flat, table-like surface that is ideal for transporting and conveying products. They are commonly used in bottling and canning operations, as well as in other applications where products need to be moved smoothly and efficiently.

Company Introduction

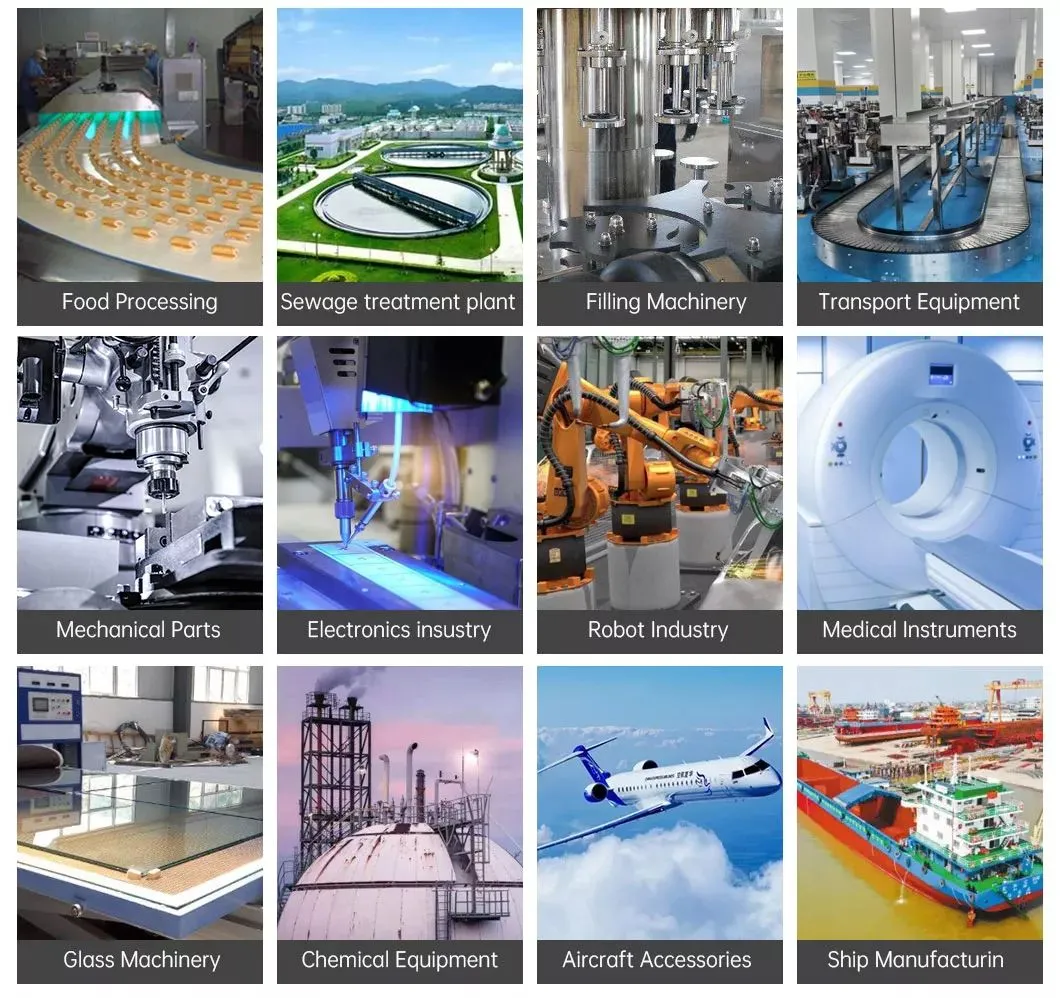

Our company is a leading player in the Chinese chain market, offering a wide range of high-quality products including leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, and table top chains. We have state-of-the-art CNC production equipment and fully automated assembly lines, allowing us to produce chains that meet the highest standards of quality and reliability. We are committed to providing our customers with the best possible products and service, and we welcome inquiries from customers around the world.

Product Promotion

If you are looking for high-quality, reliable chains for your automated packaging machinery, look no further than our company. Our chains are designed to withstand the heaviest loads and highest stresses, ensuring smooth and efficient operation of your machines. Plus, with our competitive prices and exceptional customer service, you can be confident that you are getting the best possible value for your investment. Contact us today to learn more or to place an order.

Q&A

Q: What is the maximum load capacity of leaf chains?

A: The maximum load capacity of leaf chains varies depending on a number of factors, including the size of the chain, the materials used, and the type of application. In general, leaf chains are capable of handling very heavy loads and high stresses.

Q: How are leaf chains lubricated?

A: Leaf chains can be lubricated using a variety of methods, including oil bath lubrication, drip lubrication, and spray lubrication. The method used will depend on the specific application and operating conditions of the machinery.

Q: Are leaf chains suitable for use in high-speed applications?

A: Leaf chains can be used in high-speed applications, although they may not be the best choice for all applications. In general, leaf chains are most suitable for applications that require high strength and durability, rather than high speed.

Q: How long do leaf chains typically last?

A: The lifespan of a leaf chain depends on a variety of factors, including the materials used, the load capacity of the chain, and the operating conditions of the machinery. In general, leaf chains can last for many years with proper maintenance and lubrication.

Q: Can leaf chains be customized to fit specific applications?

A: Yes, leaf chains can be customized to fit specific applications. Our company offers a wide range of customization options, including chain size, plate thickness, and pin diameter, to ensure that our chains meet the exact needs of each customer.