Sustainable Practices in Leaf Chain Manufacturing

Introduction

Leaf chain manufacturing is an essential component of the industrial sector, with a wide range of applications in various industries. Sustainable manufacturing practices are becoming increasingly important in the chain-making industry, as businesses seek to reduce their environmental impact and improve efficiency. In this article, we will explore some of the sustainable practices that are being implemented in leaf chain manufacturing.

Efficient Use of Energy

One of the most important sustainable practices in leaf chain manufacturing is the efficient use of energy. Chain manufacturers are investing in energy-efficient equipment and processes, including the use of renewable energy sources such as solar and wind power. By reducing energy consumption, manufacturers can lower their carbon footprint and reduce operating costs at the same time.

Recycling and Waste Reduction

Another important aspect of sustainable leaf chain manufacturing is recycling and waste reduction. Chain manufacturers are implementing recycling programs to reuse materials such as steel and plastic, reducing the amount of waste sent to landfills. In addition, manufacturers are investing in innovative technologies to reduce waste during the production process, such as 3D printing and laser cutting.

Water Conservation

Water conservation is another sustainable practice that is gaining traction in the leaf chain manufacturing industry. Manufacturers are implementing water-saving technologies such as closed-loop cooling systems, which recycle water to minimize usage. In addition, manufacturers are exploring ways to reduce water usage during the production process, such as using dry machining techniques instead of coolant-based methods.

Employee Safety and Well-Being

Sustainable leaf chain manufacturing also includes a focus on employee safety and well-being. Manufacturers are investing in ergonomic equipment and processes to reduce the risk of workplace injuries and improve employee comfort. In addition, manufacturers are implementing wellness programs to promote employee health and reduce absenteeism.

Application of Sustainable Practices in Leaf Chain Manufacturing

The application of sustainable practices in leaf chain manufacturing has the potential to reduce environmental impact, improve efficiency, and promote economic stability. By implementing sustainable practices, chain manufacturers can reduce costs, enhance their reputation, and strengthen relationships with customers.

Company Introduction and Product Promotion

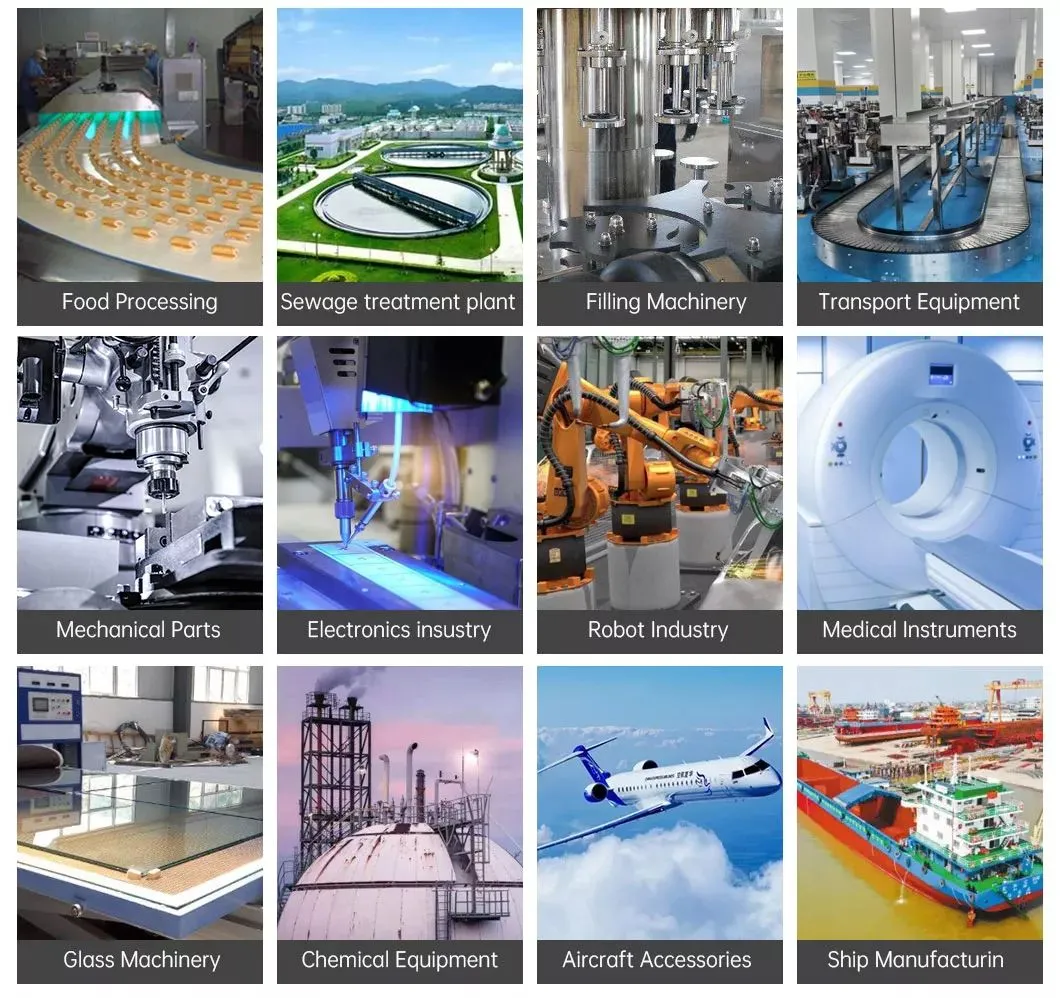

Our company is a leading manufacturer of leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprockets chains, and table top chains in the Chinese chain market. Our state-of-the-art automated CNC production and assembly equipment ensures consistent quality and on-time delivery.

Our products are known for their durability and reliability, and we offer them at competitive prices with exceptional customer service. We welcome custom orders and invite customers to visit our website at https://table-top-chains.com to learn more about our table top chains. Please visit our factory image at

Q&A

Q1: What materials are used to manufacture leaf chains?

A: Leaf chains are typically made from high-strength steel alloys, although some manufacturers may use other materials such as stainless steel or plastic.

Q2: How are leaf chains lubricated?

A: Leaf chains can be lubricated using various methods, including the use of oil or grease, or the application of a dry film lubricant.

Q3: Can leaf chains be used in high-temperature applications?

A: Yes, leaf chains are often used in high-temperature applications, and can be designed to withstand temperatures up to 600 degrees Fahrenheit.

Q4: How are leaf chains tested for quality?

A: Leaf chains are tested for quality using various methods, including tensile strength testing, hardness testing, and wear testing.

Q5: Can leaf chains be customized for specific applications?

A: Yes, leaf chains can be customized for specific applications based on factors such as load capacity, length, and attachment style.