Signs Your Leaf Chain Needs Replacement

Introduction

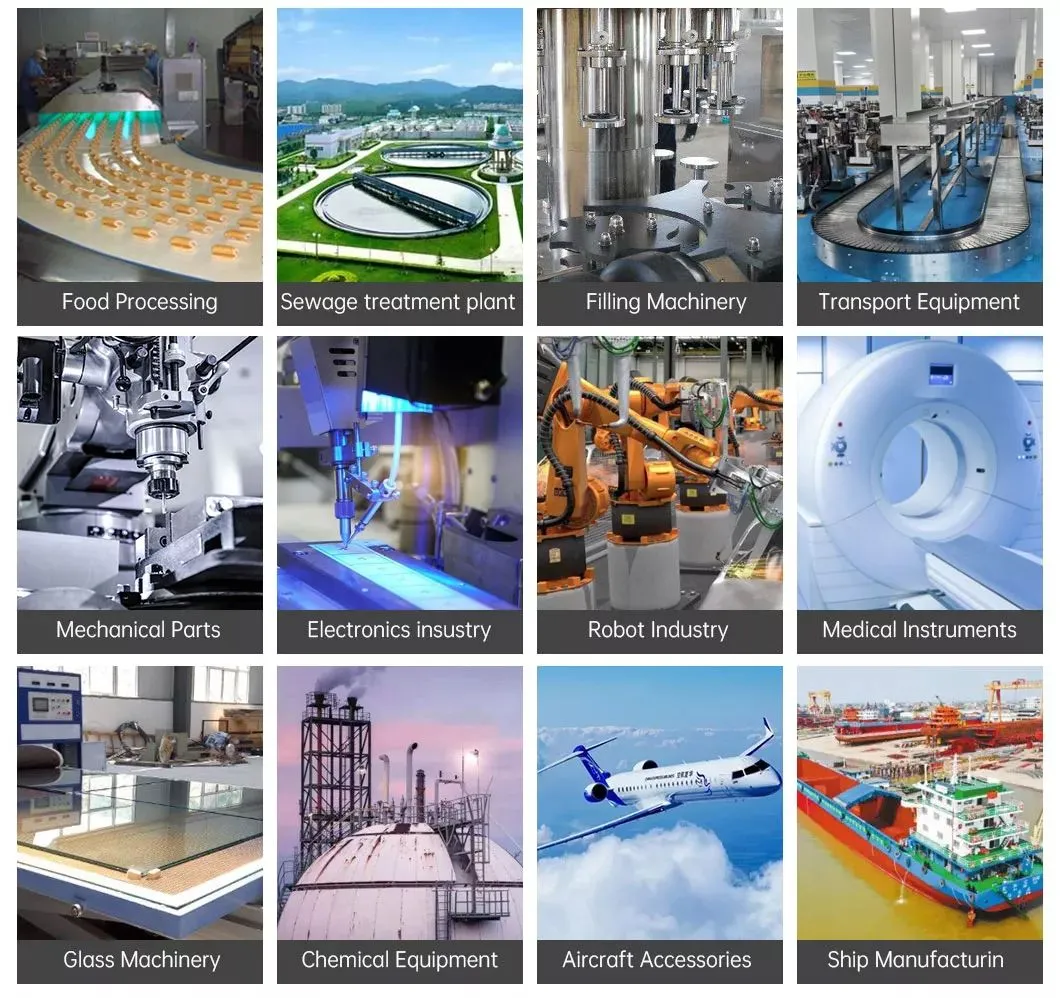

A leaf chain is an integral component of most material handling systems. It is commonly used in applications where there is a need for a strong, durable, and flexible chain that can withstand the rigors of heavy-duty use. Over time, leaf chains can wear out and become damaged, leading to significant problems in the performance of the material handling system. In this article, we explore the signs that your leaf chain needs replacement.

Signs Your Leaf Chain Needs Replacement

- Excessive Wear

- Increased Noise

- Poor Performance

- Visible Damage

- Increased Maintenance

One of the most common signs that your leaf chain needs replacement is excessive wear. Over time, the chain will begin to show signs of wear, such as elongation, distortion, and stretching.

If you notice an increase in the noise levels of your material handling system, it may be an indication that your leaf chain needs replacement. The noise can be caused by a loose chain or due to the presence of broken or damaged links.

If your material handling system is exhibiting poor performance, it may be due to a worn or damaged leaf chain. Poor performance can manifest as reduced speed, difficulty in starting, or intermittent operation.

Inspect your leaf chain regularly for visible signs of damage, such as bent, broken, or damaged links. If you notice any visible damage, it is essential to replace the chain immediately to prevent further damage to your material handling system.

If your material handling system requires more frequent maintenance than usual, it may be a sign that your leaf chain needs replacement. Over time, a worn or damaged chain can cause other components of the system to wear out faster, leading to increased maintenance costs.

Image source: https://leaf-chains.net/wp-content/uploads/2023/05/Application.webp

Conclusion

Leaf chains are an essential component of most material handling systems. It is vital to inspect your chain regularly for signs of wear and damage. If you notice any of the signs mentioned above, it is crucial to replace your leaf chain immediately to prevent further damage to your material handling system. To learn more about our products, including table top chains, please visit https://table-top-chains.com.

Company Promotion and Introduction

We are a leading company in the chain market in China, offering a wide range of products, including leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprockets chains, and table top chains. We utilize various fully automated CNC production equipment and automatic assembly equipment to ensure the quality of our products. Our products are competitively priced, and we offer excellent customer service. We also provide customization services for our customers. Please visit our website for more information: https://leaf-chains.net.

Image source: https://leaf-chains.net/wp-content/uploads/2024/03/factory.webp

Q&A

- Q: How often should I inspect my leaf chain for signs of wear and damage?

- Q: Can a worn or damaged leaf chain cause other components of my material handling system to wear out faster?

- Q: How long does a leaf chain usually last?

- Q: Can I repair a damaged leaf chain?

- Q: How do I determine the right leaf chain size for my material handling system?

A: It is recommended to inspect your leaf chain regularly, at least once a month.

A: Yes, a worn or damaged leaf chain can cause other components of your material handling system to wear out faster, leading to increased maintenance costs.

A: The lifespan of a leaf chain depends on several factors, such as the frequency of use, the weight of the load, and the operating conditions. In general, a leaf chain can last up to five years or more if properly maintained.

A: It is recommended to replace a damaged leaf chain instead of repair. Repairing a damaged chain may weaken the structure of the chain, leading to further damage or failure.

A: To determine the right leaf chain size, you need to consider the pitch, width, and number of links required for your material handling system. It is essential to consult the manufacturer's specifications and guidelines for your particular application.