Preventative Maintenance Tips for Leaf Chains

Leaf chains are an integral part of many machines and their smooth operation is crucial for efficiency and safety. Preventative maintenance is the key to avoiding costly downtime and ensuring the longevity of your leaf chains. In this article, we will provide 25 tips for maintaining your leaf chains and keeping them in optimal condition.

1. Keep the Chain Lubricated

The most basic, yet important, tip for maintaining leaf chains is to keep them lubricated. Lubrication reduces friction and wear and tear on the chain. Without proper lubrication, the chain can seize up, which can cause damage to both the chain and the machine it is operating.

2. Choose the Right Lubricant

Choosing the right lubricant is important for chain maintenance. Not all lubricants are created equal, and using the wrong type can cause damage to the chain. Consult the manufacturer's recommendations for the right lubricant to use.

3. Regularly Inspect the Chain

Regular inspections can help you catch potential problems before they become major issues. Look for signs of wear and tear, such as elongation or bending. Address any issues as soon as possible.

4. Proper Tensioning

Proper chain tensioning is important for ensuring smooth operation and extending the life of the chain. Too much tension can cause excessive wear and tear, while too little tension can cause the chain to slip off its sprockets.

5. Replace Worn Chains

Even with proper maintenance, leaf chains will eventually wear out. Replace chains before they become too worn to avoid damage to the machine or other components.

6. Check for Corrosion

Corrosion can cause serious damage to leaf chains. Check for signs of rust or other types of corrosion and address any issues as soon as possible.

7. Proper Storage

Proper storage is important for maintaining leaf chains. Store chains in a clean, dry area and protect them from dust and other contaminants.

8. Check for Misalignment

Misaligned chains can cause excessive wear and tear. Check for proper alignment and address any issues as soon as possible.

9. Keep Chains Clean

Keeping chains clean can help prevent contamination and reduce wear and tear. Clean chains regularly using a mild detergent and rinse with water.

10. Use the Right Sprockets

Using the right sprockets is important for ensuring proper chain operation. Consult the manufacturer's recommendations for the right sprockets to use with your chain.

11. Avoid Overloading

Overloading can cause excessive wear and tear on leaf chains. Avoid overloading machines and ensure they are operating at their rated capacity.

12. Keep Proper Slack

Proper slack is important for ensuring smooth chain operation. Check for proper slack and adjust as necessary.

13. Avoid Abrasives

Abrasives can cause serious damage to leaf chains. Avoid operating chains in areas with abrasive materials.

14. Regularly Clean Sprockets

Clean sprockets can help prevent wear and tear on leaf chains. Regularly clean sprockets using a mild detergent and rinse with water.

15. Ensure Proper Alignment

Proper alignment is important for ensuring smooth chain operation. Check for proper alignment and adjust as necessary.

16. Use Proper Chain Tensioner

A proper chain tensioner is important for ensuring optimal chain operation. Consult the manufacturer's recommendations for the right tensioner to use with your chain.

17. Address Issues Immediately

Address any chain issues as soon as possible to prevent further damage to the chain or machine.

18. Regularly Check for Elongation

Checking for elongation can help you catch potential chain issues before they become major problems. Consult the manufacturer's recommendations for how often to check for elongation.

19. Use Proper Chain Attachments

Using the right chain attachments is important for ensuring proper chain operation. Consult the manufacturer's recommendations for the right attachments to use with your chain.

20. Avoid Harsh Chemicals

Harsh chemicals can cause damage to leaf chains. Avoid operating chains in areas with harsh chemicals.

21. Regularly Check for Bending

Checking for bending can help you catch potential chain issues before they become major problems. Consult the manufacturer's recommendations for how often to check for bending.

22. Use Proper Chain Guides

Using the right chain guides is important for ensuring proper chain operation. Consult the manufacturer's recommendations for the right guides to use with your chain.

23. Check for Cracks

Checking for cracks can help you catch potential chain issues before they become major problems. Consult the manufacturer's recommendations for how often to check for cracks.

24. Use Proper Chain Tension

Proper chain tension is important for ensuring optimal chain operation. Consult the manufacturer's recommendations for the right tension to use with your chain.

25. Regularly Check for Wear and Tear

Checking for wear and tear can help you catch potential chain issues before they become major problems. Consult the manufacturer's recommendations for how often to check for wear and tear.

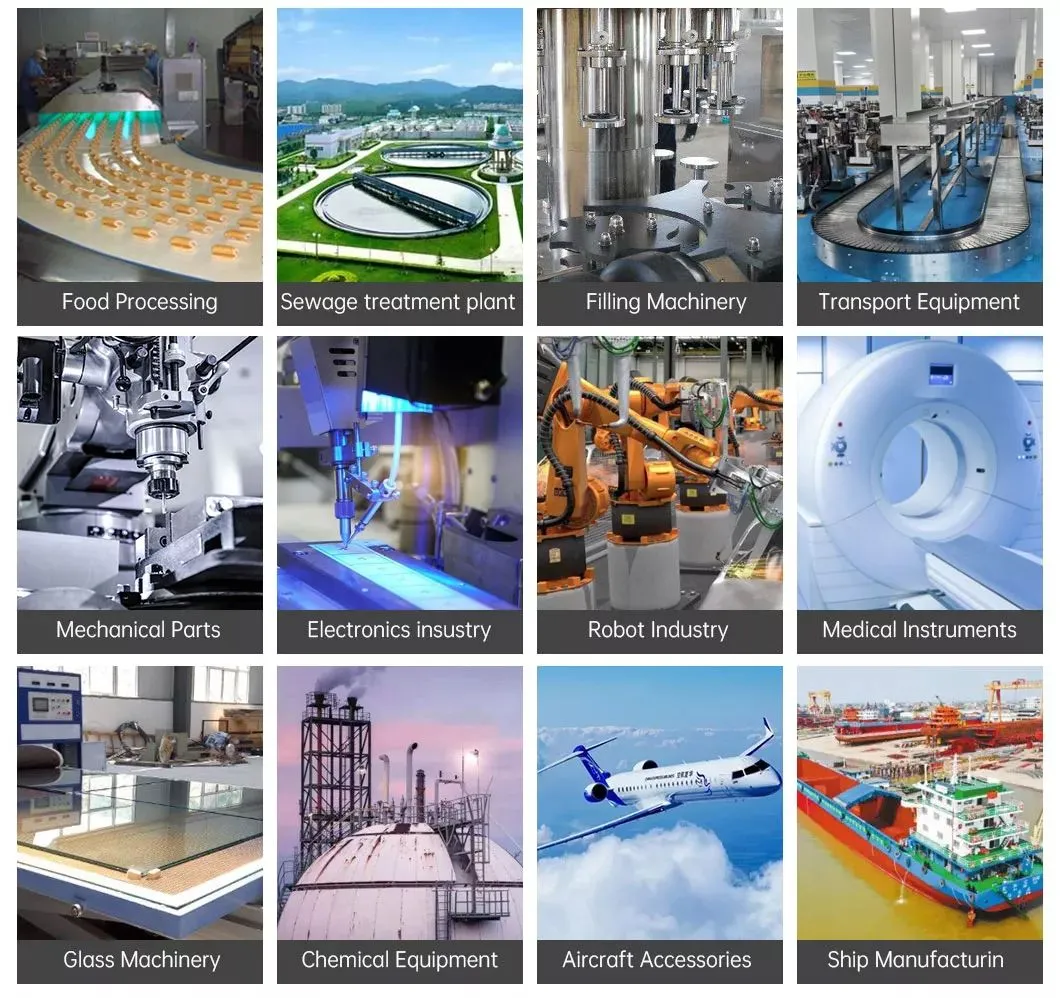

Thank you for reading our preventative maintenance tips for leaf chains. At our company, we specialize in producing high-quality leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, table top chains, and more. Our state-of-the-art production and assembly equipment ensures the highest level of precision and quality. We pride ourselves on providing exceptional products and services at competitive prices. For more information, please visit table-top-chains.com.

Q&A

1. How often should I inspect my leaf chains?

You should inspect your leaf chains regularly, following the manufacturer's recommendations for how often to inspect. This can help you catch potential issues before they become major problems.

2. What lubricant should I use for my leaf chains?

You should consult the manufacturer's recommendations for the right lubricant to use with your chain. Not all lubricants are created equal, and using the wrong type can cause damage to the chain.

3. Can I use my leaf chains in areas with abrasive materials?

Avoid operating chains in areas with abrasive materials, as this can cause serious damage to the chain.

4. What should I do if I notice signs of wear and tear on my leaf chains?

If you notice signs of wear and tear, address the issue as soon as possible to prevent further damage to the chain or machine.

5. How can I ensure proper tensioning of my leaf chains?

Proper chain tensioning is important for ensuring smooth operation and extending the life of the chain. Consult the manufacturer's recommendations for the right tension to use with your chain.