Online Courses on Leaf Chain Maintenance and Repair

Leaf chains are an essential component in many industrial applications, providing necessary support and strength to the machinery. The efficient functioning of leaf chains requires regular maintenance and timely repairs. To ensure the proper handling and maintenance of leaf chains, it is essential to have a basic understanding of the component and its repair process.

What Are Leaf Chains?

Leaf chains are a type of industrial chain that comprises metal plates or links joined together using pins. They are commonly used in material handling equipment, such as forklift trucks, cranes, and conveyor belts, due to their high strength and durability.

How Do Leaf Chains Work?

Leaf chains work by transmitting power from the equipment's motor to the machinery's moving parts. The chain's links are designed to engage with sprockets or pulleys, which are attached to the motor and the machinery's moving parts, respectively. When the motor rotates, the chain's links move, causing the machinery's parts to move as well.

What Causes Leaf Chains to Fail?

Leaf chains can fail due to a variety of reasons, including excessive wear and tear, corrosion, and improper maintenance. Inadequate lubrication and overloading of the chain can also cause it to fail prematurely.

How Can Leaf Chain Failure be Prevented?

Proper maintenance and regular inspections can help prevent leaf chain failure. It is essential to keep the chain clean and adequately lubricated and to replace it when signs of wear and tear are evident. Overloading the chain should also be avoided, and the machinery's operating conditions should be monitored to ensure the chain is not subjected to excessive stress.

What Are the Benefits of Online Leaf Chain Maintenance and Repair Courses?

Online courses on leaf chain maintenance and repair provide an opportunity for individuals to learn about the component's handling and repair processes from the comfort of their own homes or workplaces. The courses typically cover topics such as chain selection, lubrication, inspection, and repair techniques, and can help individuals develop the necessary skills to maintain and repair leaf chains effectively.

Why Choose Our Company for Leaf Chain Products?

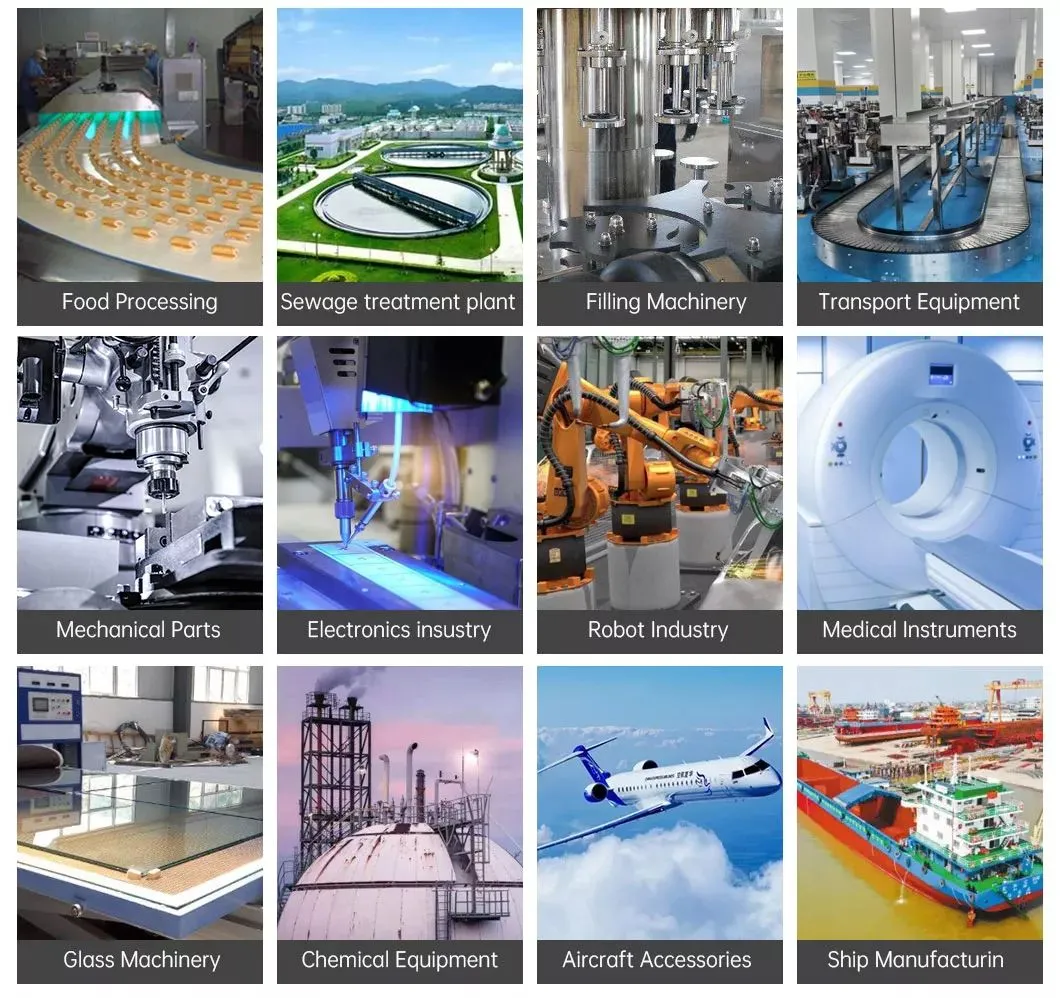

Our company is a leading player in the Chinese chain market, providing a wide range of high-quality products, including leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprockets chains, and table top chains. We have state-of-the-art automatic CNC production equipment and fully automatic assembly equipment, ensuring the consistent quality of our products.

We take pride in providing our customers with competitive prices and personalized service. Our products are customizable, and we welcome customers to come to us with their specific needs and requirements.

If you are looking for high-quality leaf chains or any other type of industrial chain, visit our website or contact us directly. You can also visit our website, table-top-chains.com, for more information on our table top chains.

Q&A

Q1. How often should leaf chains be inspected?

A1. Leaf chains should be inspected at regular intervals, as specified by the manufacturer or equipment supplier. Typically, inspections are done once every six months or every 2000-4000 hours of operation.

Q2. Can leaf chains be repaired?

A2. Yes, leaf chains can be repaired. However, the extent of the repair depends on the damage sustained by the chain. Minor repairs, such as replacing damaged links or pins, can be carried out onsite, while major repairs may require the chain to be sent to a specialist repair center.

Q3. What is the most common cause of leaf chain failure?

A3. The most common cause of leaf chain failure is wear and tear due to normal use. However, other factors such as corrosion, inadequate lubrication, and overloading can also lead to chain failure.

Q4. How can I tell if my leaf chain needs lubrication?

A4. Signs that your leaf chain needs lubrication include unusual noises during operation, visible wear and tear on the chain, and increased resistance when the chain is in motion.

Q5. Can leaf chains be used in corrosive environments?

A5. Yes, leaf chains can be used in corrosive environments, provided they are made from corrosion-resistant materials such as stainless steel or nickel-plated steel. Proper maintenance and lubrication also help prolong the chain's lifespan in corrosive environments.