Leaf Chains in Elevator and Lifting Equipment

Elevators and lifting equipment are essential for moving materials and people in various settings. They are used in industries such as construction, manufacturing, and transportation. Leaf chains are an important component of these machines, providing stability and strength to the lifting mechanism. In this article, we will discuss the application of leaf chains in elevator and lifting equipment, their benefits, and how to choose the right leaf chain for your equipment.

What Are Leaf Chains?

Leaf chains are made up of inner and outer link plates with pins and bushings connecting them. They are designed to provide high tensile strength and resistance to fatigue and wear. Due to their simple yet effective design, they are commonly used in heavy-duty lifting applications such as forklifts, cranes, and elevators.

Benefits of Leaf Chains

The benefits of using leaf chains in elevator and lifting equipment include:

- High strength and durability

- Low maintenance

- Resistant to wear and corrosion

- Cost-effective

Choosing the Right Leaf Chain

Choosing the right leaf chain for your equipment is important to ensure its longevity and efficient operation. Factors to consider when selecting a leaf chain include:

- Load capacity

- Pitch and size

- Environmental conditions

- Frequency of use

It is recommended to consult with a leaf chain supplier to ensure you choose the right product for your specific application.

Application of Leaf Chains

Leaf chains are commonly used in elevator and lifting applications, particularly in situations where heavy loads need to be lifted. They can also be used in conveyor systems and other heavy-duty equipment. Leaf chains are preferred over roller chains in these applications due to their high strength and durability.

Cotter Type Chain, Conveyor Chain, Bush Chain, and More

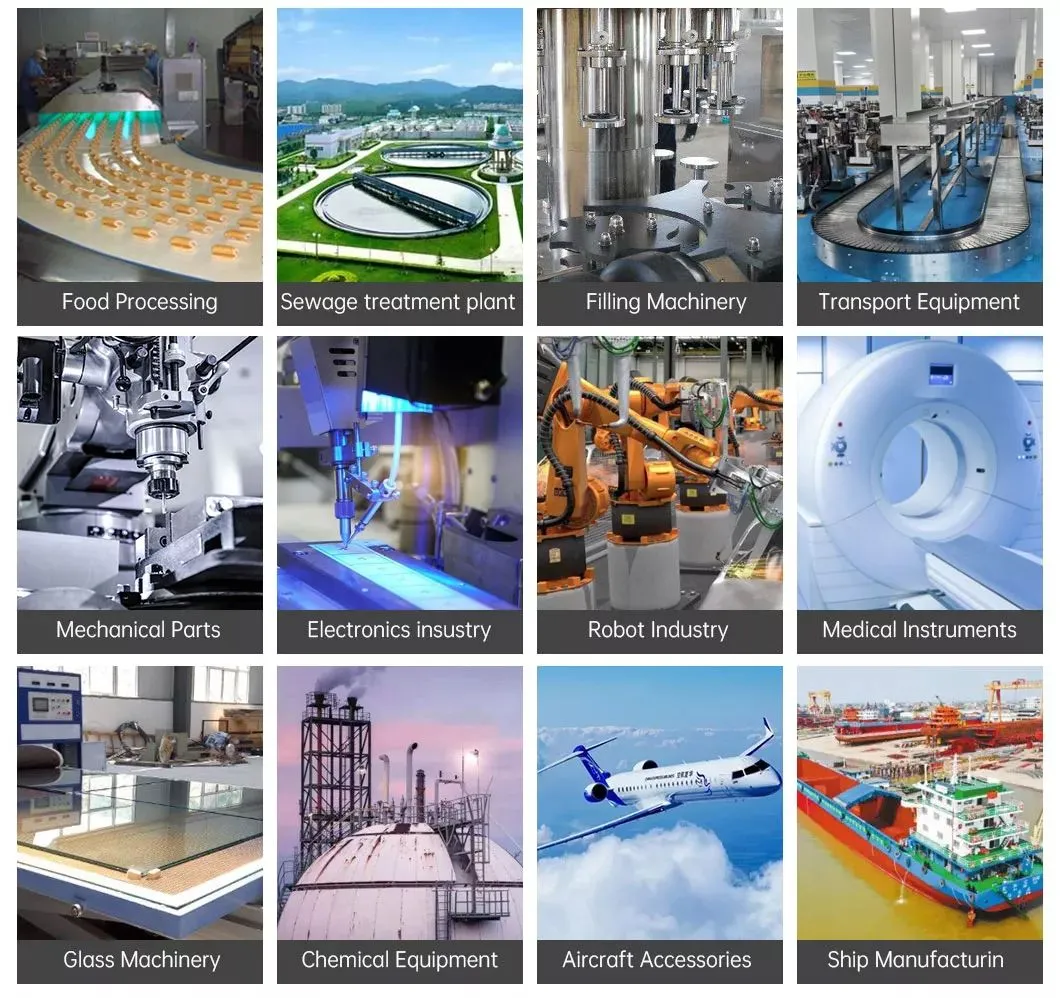

In addition to leaf chains, our company offers a wide range of chain products including cotter type chain, conveyor chain, bush chain, double flex chain, sprocket chains, table top chains and more. Our products are manufactured using state-of-the-art automated equipment to ensure high quality and consistency. We pride ourselves on our competitive pricing and excellent customer service, and we welcome custom orders based on specific needs. For more information on our products, visit our website at https://table-top-chains.com.

Q&A

Q: How often should leaf chains be inspected for wear?

A: Leaf chains should be inspected on a regular basis, with frequency dependent on usage. It is recommended to conduct inspections every 500-1000 hours of operation.

Q: What lubricant should be used with leaf chains?

A: It is recommended to use a high-quality chain lubricant that is formulated for leaf chains. Consult with a supplier for specific product recommendations.

Q: Can leaf chains be repaired?

A: It is possible to repair leaf chains, but it is recommended to replace the chain if it is worn or damaged beyond repair. Repairing a damaged chain can compromise its strength and increase the risk of failure.

Q: What is the maximum load capacity for leaf chains?

A: The maximum load capacity for a leaf chain depends on its size and pitch. Consult with a supplier to determine the load capacity for your specific chain.

Q: What is the difference between leaf chains and roller chains?

A: Leaf chains are designed for heavy-duty applications that require high strength and durability. They are preferred over roller chains for lifting and conveyor applications. Roller chains are used in lighter-duty applications such as bicycles and motorcycles.