Leaf chain retrofitting advice for enhanced industrial safety

Introduction

Leaf chains are important components used in many industrial applications. These chains are used in various equipment, including forklifts, cranes, and hoists. They are designed to be highly durable and reliable, but over time, they can become worn or damaged. When this happens, it is important to retrofit the leaf chain to ensure that the equipment remains safe and functional. In this article, we will provide advice on how to retrofit leaf chains for enhanced industrial safety.

Why Retrofitting Leaf Chains is Important

Retrofitting leaf chains is important because it helps to prevent equipment failure and accidents in the workplace. When leaf chains become worn or damaged, they can break or malfunction, which can lead to equipment failure. This can cause damage to the equipment or even cause injury to the operator or other workers.

Factors to Consider When Retrofitting Leaf Chains

Chain Size

When retrofitting leaf chains, it is important to consider the size of the chain. Chains come in different sizes, and it is important to choose the right size for the equipment. Using the wrong size chain can lead to equipment failure and accidents.

Chain Strength

Another factor to consider when retrofitting leaf chains is the strength of the chain. Chains come in different strength ratings, and it is important to choose a chain with the right strength to support the equipment. Using a chain that is too weak can lead to equipment failure and accidents.

Operating Environment

The operating environment is also an important factor to consider when retrofitting leaf chains. Different environments have different conditions that can affect the performance of the chain. For example, an environment with high humidity or corrosive chemicals can cause the chain to deteriorate faster. It is important to choose a chain that is suitable for the operating environment.

Steps for Retrofitting Leaf Chains

Step 1: Remove the Old Chain

The first step in retrofitting leaf chains is to remove the old chain from the equipment. This can be done by loosening the tension on the chain and removing the connecting links that hold the chain together.

Step 2: Measure the Chain Length

After removing the old chain, it is important to measure the length of the chain. This will help to ensure that the new chain is the right size for the equipment.

Step 3: Choose the Right Chain

Based on the factors mentioned above, choose the right chain for the equipment. Consider the chain size, strength, and operating environment when making this decision.

Step 4: Install the New Chain

Once the right chain has been chosen, install the new chain on the equipment. This can be done by threading the chain through the sprockets and connecting the links to hold the chain together. Adjust the tension on the chain as needed.

Using Table Top Chains in Retrofitted Equipment

Table top chains are an excellent choice for retrofitting equipment that requires a smooth and flat conveying surface. These chains are versatile and can be used in a variety of applications. They are highly durable and reliable, making them a great choice for retrofitting leaf chains.

If you are interested in purchasing table top chains, please visit our website at https://table-top-chains.com

Company Promotion and Introduction

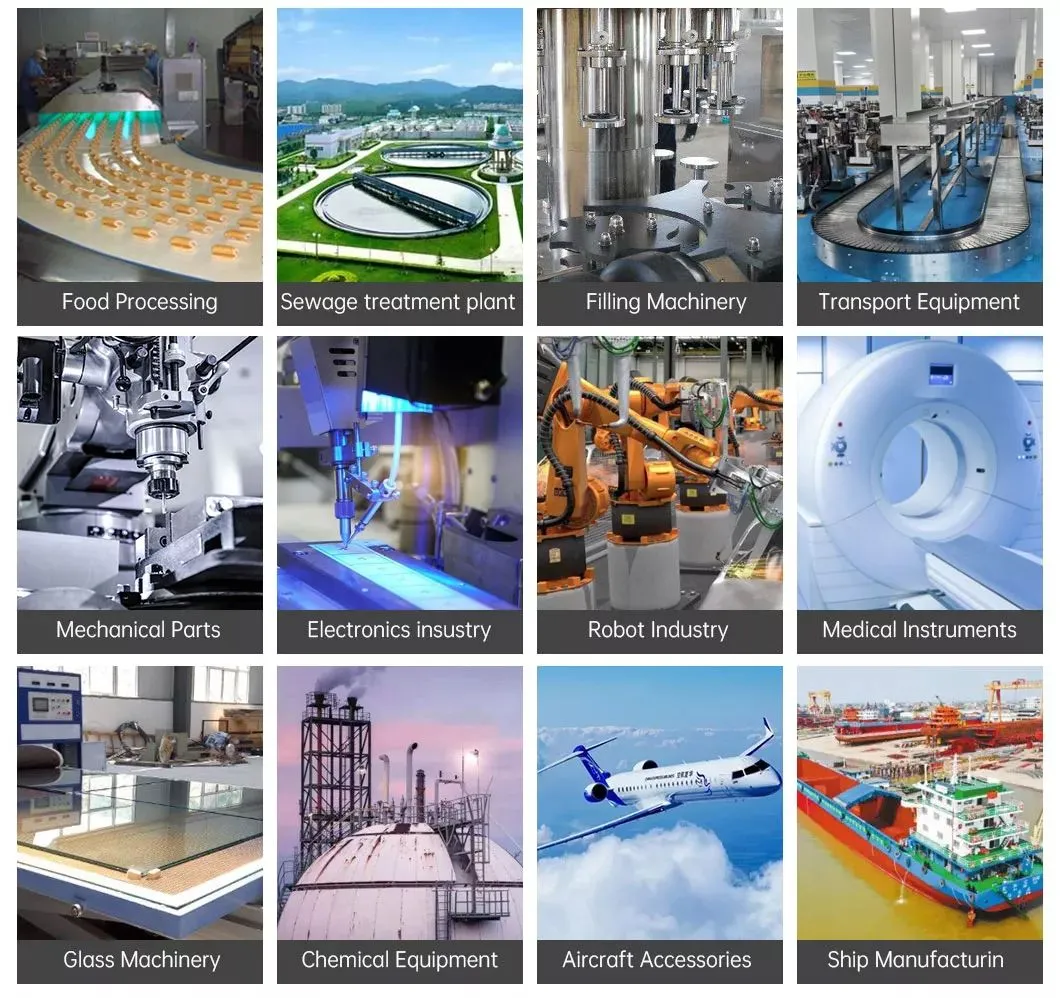

We are a leading company in the chain market in China. Our products include leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, and table top chains. We have various automatic CNC production equipment and automatic assembly equipment. Our products are of high quality, and we offer competitive prices and excellent customer service. We welcome customers to send us drawings or samples for customization.

Q&A

Q1: How often should leaf chains be checked for wear and tear?

A1: Leaf chains should be checked for wear and tear regularly, according to the equipment manufacturer's recommendations. This will help to identify any potential problems with the chain before they become serious.

Q2: What are some signs that a leaf chain needs to be replaced?

A2: Some signs that a leaf chain needs to be replaced include visible signs of wear and tear, such as elongation or corrosion, as well as unusual noises or vibrations during operation.

Q3: Can any type of chain be used as a replacement for a leaf chain?

A3: No, not every type of chain can be used as a replacement for a leaf chain. It is important to use a chain that is specifically designed for the equipment and operating environment.

Q4: Can leaf chains be repaired instead of replaced?

A4: In some cases, leaf chains can be repaired instead of replaced. However, this should only be done by a professional who has experience with repairing leaf chains.

Q5: How can I ensure that I am using the right leaf chain for my equipment?

A5: To ensure that you are using the right leaf chain for your equipment, consult with the equipment manufacturer or a professional who has experience with retrofitting leaf chains. They can help you to choose the right chain based on the equipment size, strength, and operating environment.