Leaf Chain Price vs. Performance Analysis

Introduction

Leaf chains are an essential component in many industrial applications, including forklifts, cranes, and hoists. When it comes to purchasing leaf chains, buyers are often confronted with a choice between different performance levels and prices. In this article, we will analyze the price vs. performance trade-off and provide guidance for selecting the best leaf chain for your application.

Types of Leaf Chains

Standard Leaf Chains

Standard leaf chains are the most common type, which can be used in most applications. They are affordable and offer decent performance for general purposes.

Heavy-Duty Leaf Chains

Heavy-duty leaf chains are designed for heavy loads and high shock loads. They have thicker plates and wider barrels to increase strength and durability. The price of heavy-duty leaf chains is higher than standard chains, but they can withstand much more demanding conditions.

Corrosion-Resistant Leaf Chains

Corrosion-resistant leaf chains are made from materials that can withstand harsh environments, such as saltwater or acidic conditions. They are more expensive than standard chains but are necessary for certain applications.

Factors Affecting Leaf Chain Performance

Load Capacity

The load capacity is the maximum load that a leaf chain can bear before breaking. It depends on the size and material of the chain. Heavy-duty chains have higher load capacities than standard chains.

Wear Resistance

Wear resistance is the ability of the chain to resist wear and elongation. Heavy loads, high speeds, and harsh environments can cause chains to wear out quickly. Chains made from high-grade materials and with special coatings have better wear resistance than standard chains.

Fatigue Resistance

Fatigue resistance is the ability of the chain to withstand repeated stress cycles without cracking or breaking. Chains with thicker plates and wider barrels have better fatigue resistance than standard chains.

Corrosion Resistance

Corrosion resistance is the ability of the chain to resist rust and corrosion. Chains made from stainless steel or with special coatings have better corrosion resistance than standard chains.

Price vs. Performance Analysis

When selecting a leaf chain, it is important to find a balance between price and performance. Higher performance chains are typically more expensive, but they can last longer and reduce maintenance costs in the long run. In contrast, lower performance chains are cheaper, but they may require more frequent replacements, which can increase downtime and maintenance costs.

Application Examples

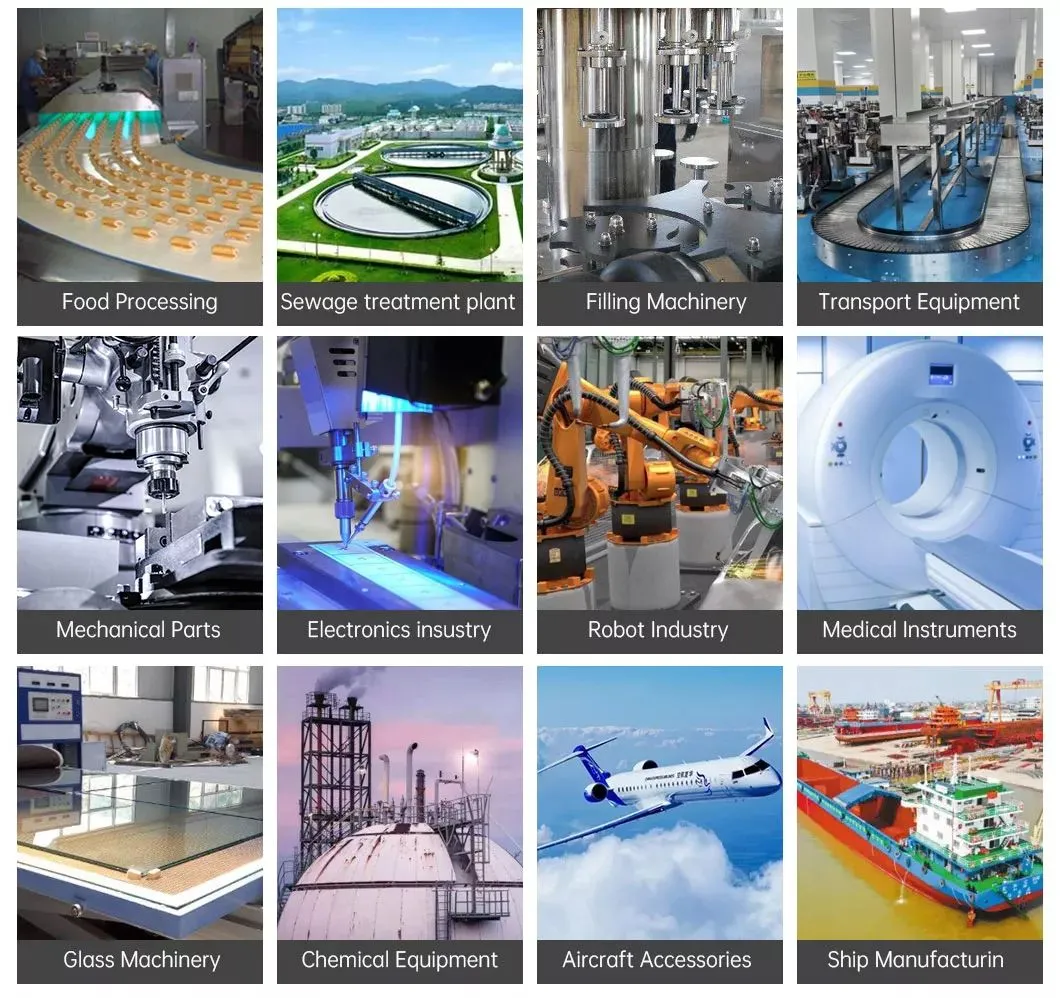

Leaf chains are used in a wide variety of applications. For example, in forklifts, leaf chains transmit the power from the engine to the wheels. In cranes, leaf chains are used to lift heavy loads. In hoists, leaf chains are used to move materials up and down.

Company Promotion

Our company is a leading player in the Chinese chain market. We offer a wide range of high-quality products, including leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, and table top chains. Our fully automated production and assembly equipment ensures consistent quality and timely delivery. We pride ourselves on offering competitive prices and excellent customer service. We welcome customers to send us samples and drawings for custom chain solutions. For more information about our table top chains, please visit https://table-top-chains.com.

Q&A

Q1: Can leaf chains be repaired?

A: Yes, leaf chains can be repaired by replacing damaged links or by shortening the chain if the damage is not extensive.

Q2: Can leaf chains be used in high-temperature environments?

A: Yes, leaf chains made from special heat-resistant materials can be used in high-temperature environments.

Q3: How often should leaf chains be lubricated?

A: The lubrication frequency depends on the application and the environment. In general, leaf chains should be lubricated regularly to reduce wear and prevent corrosion.

Q4: Can leaf chains be used in corrosive environments?

A: Yes, corrosion-resistant leaf chains are designed for use in corrosive environments.

Q5: How can I determine the right leaf chain for my application?

A: The right leaf chain depends on several factors, including load capacity, wear resistance, fatigue resistance, and corrosion resistance. Our experts can help you select the best chain for your specific application.