Leaf Chain Elongation Measurement Guide

Leaf chains are widely used in various industries, such as forklifts and construction equipment. It is important to measure the elongation of the chains regularly to ensure their proper function and prevent safety hazards. In this guide, we will provide a detailed instruction on how to measure the elongation of leaf chains.

What is Leaf Chain Elongation?

Leaf chain elongation refers to the increase in the length of the chain due to wear and tear over time. Elongation can cause the chain to become loose, reduce its load-carrying capacity, and eventually lead to failure and safety hazards.

Why is Leaf Chain Elongation Important?

Measuring the elongation of leaf chains is important for several reasons:

- To ensure the proper function of the equipment

- To prevent safety hazards

- To avoid expensive repairs or replacements

How to Measure Leaf Chain Elongation?

To measure the elongation of leaf chains, follow these steps:

- Measure the length of 10 pitches of the chain

- Apply a load to the chain equivalent to 20% of its breaking load

- Measure the length of 10 pitches of the chain again

- Compare the two measurements. If the elongation is more than 3%, the chain needs to be replaced.

When Should Leaf Chains be Replaced?

Leaf chains should be replaced when:

- The elongation is more than 3%

- The wear on the chain is more than 8% of the original thickness

- Any signs of cracking or damage are present

What is the Best Way to Maintain Leaf Chains?

The best way to maintain leaf chains is to:

- Regularly measure the elongation and wear of the chains

- Use proper lubrication to reduce wear and corrosion

- Store the chains in a dry and clean environment to avoid contamination

Using Leaf Chains in Conveyor Systems

Leaf chains are commonly used in conveyor systems, where they provide reliable and efficient power transmission. Table top chains are a great alternative to leaf chains for conveyor systems, offering smoother and quieter operation. Check out our table top chains for your conveyor needs.

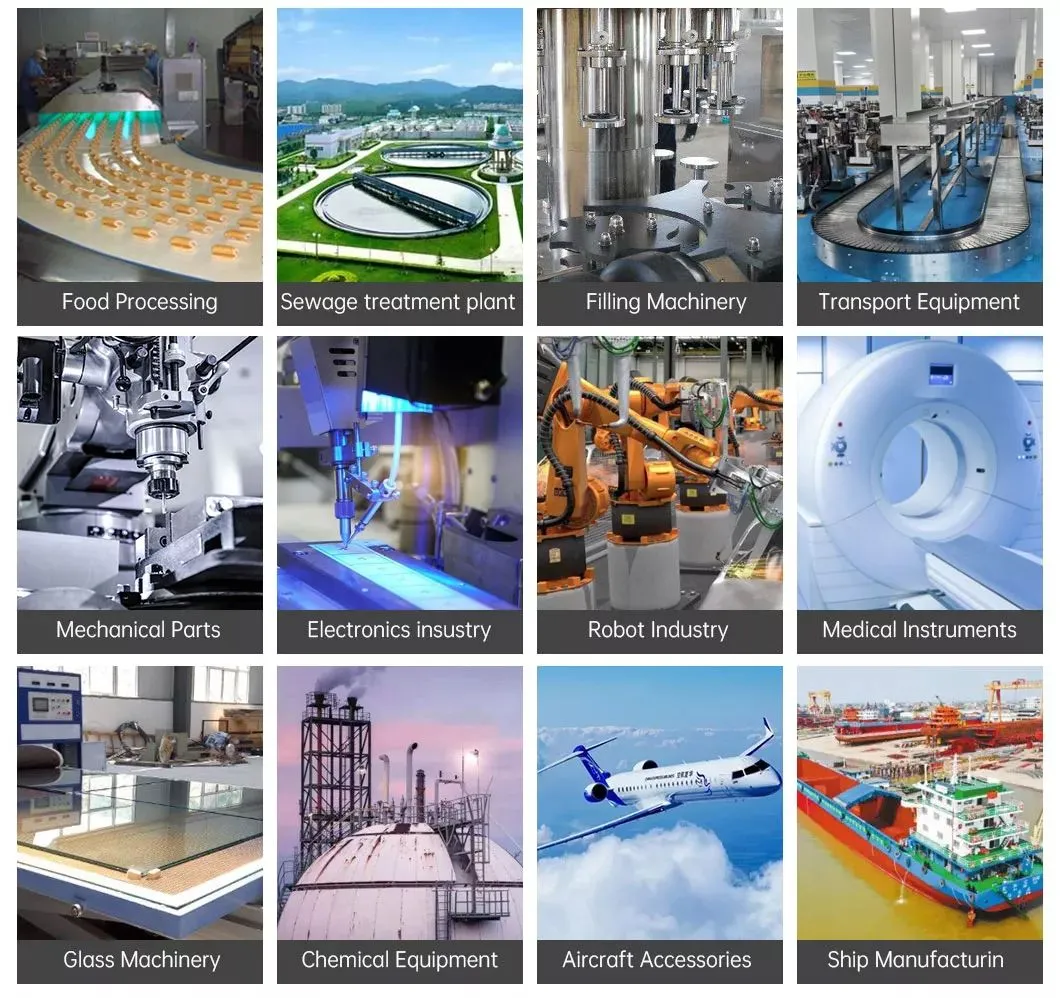

About Our Company

We are a leading company in the chain market in China, offering a wide range of products, including leaf chain, cotter type chain, conveyor chain, bush chain, double flex chain, sprockets chains, and more. Our state-of-the-art automatic CNC production and assembly equipment ensures high-quality and cost-effective products for our customers. We welcome customized orders based on your specifications and offer competitive prices and attentive service.

Q&A

Q: How often should leaf chains be measured for elongation?

A: Leaf chains should be measured for elongation at least once every 6 months or as recommended by the manufacturer.

Q: What is the difference between leaf chains and roller chains?

A: Leaf chains have a flat, leaf-shaped link that provides a larger contact surface and high tensile strength, making them suitable for heavy-duty applications. Roller chains have cylindrical rollers that reduce friction and wear, making them suitable for high-speed applications.

Q: What is the maximum allowable wear on a leaf chain?

A: The maximum allowable wear on a leaf chain is 8% of its original thickness. Beyond that, the chain should be replaced.

Q: Can leaf chains be repaired?

A: Leaf chains can be repaired in some cases, such as by replacing worn or damaged components. However, it is generally more cost-effective to replace the entire chain.

Q: How do I choose the right leaf chain for my application?

A: The right leaf chain for your application depends on several factors, such as the load capacity, speed, and environment. Consult with the manufacturer or supplier to select the appropriate chain.