Innovations in Leaf Chain Lubrication Systems for Automatic Maintenance

Leaf chains are an integral part of many industrial machines, and their proper maintenance is crucial for the smooth functioning of these machines. One of the biggest challenges in leaf chain maintenance is lubrication, and traditional manual lubrication methods can be time-consuming and labor-intensive. However, recent innovations in leaf chain lubrication systems have made it possible to automate this process, leading to increased efficiency and reduced downtime.

The Need for Leaf Chain Lubrication

Leaf chains are subject to wear and tear due to the high loads and stresses they are exposed to during machine operation. Lubrication is essential to reduce friction and wear, prevent corrosion, and extend the life of the chain. Without proper lubrication, the chain can stretch, elongate, and eventually fail, leading to costly repairs and downtime.

The Challenges of Manual Lubrication

Manual lubrication of leaf chains can be a time-consuming and labor-intensive process, especially in large industrial machines with multiple chains. It requires shutting down the machine, manually applying lubricant to each chain, and restarting the machine. This process can take hours, resulting in significant production losses and downtime. Additionally, manual lubrication can be inconsistent, with some chains receiving more or less lubrication than they need.

The Benefits of Automatic Lubrication Systems

Automatic lubrication systems have several advantages over manual lubrication methods. They can be programmed to lubricate chains at specific intervals or based on machine usage, ensuring consistent lubrication and reducing the risk of over or under-lubrication. Automatic lubrication systems also eliminate the need to shut down the machine for lubrication, leading to increased productivity and reduced downtime. Additionally, these systems can be remotely monitored and controlled, making it easier to detect and address lubrication issues before they lead to machine failure.

Types of Automatic Lubrication Systems

There are several types of automatic lubrication systems available for leaf chains, including:

- Single-point lubricators, which dispense a controlled amount of lubricant to a single chain at preset intervals or on demand.

- Multi-point lubricators, which can lubricate multiple chains at the same time.

- Circulating oil systems, which continuously circulate oil through a closed loop to lubricate multiple chains.

The Future of Leaf Chain Lubrication

The innovations in leaf chain lubrication systems are not stopping anytime soon. The industry is continually exploring new ways to automate the lubrication process while ensuring maximum efficiency and effectiveness. Some of the future developments include:

- Remote monitoring and control of lubrication systems using IoT technology.

- Development of biodegradable lubricants.

- Integration of predictive maintenance technology to detect lubrication issues before they lead to machine failure.

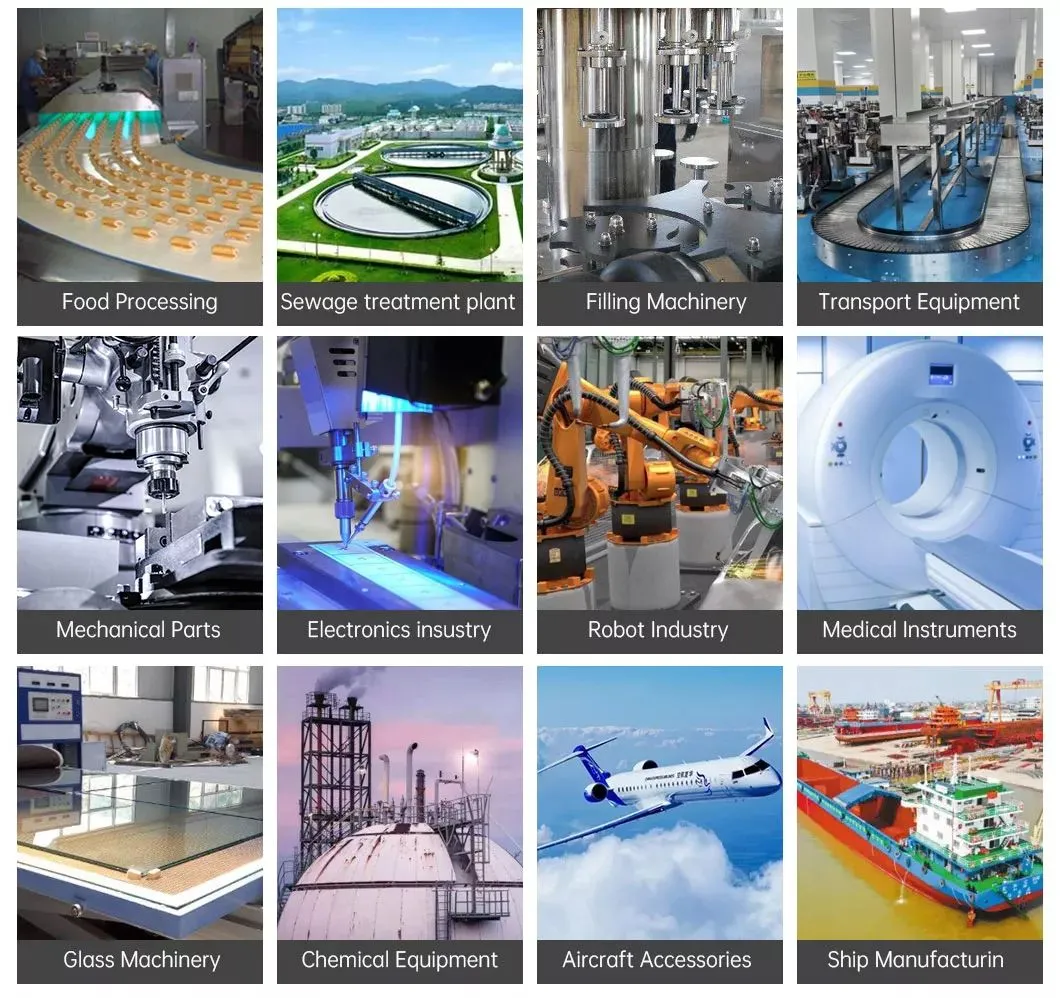

Applications of Leaf Chains

Leaf chains find applications in several industries, including:

- Material handling and lifting equipment.

- Construction machinery.

- Automotive and agricultural machinery.

- Industrial robots.

Company Promotion and Introduction

We are a leading chain manufacturer in the Chinese market. Our products include leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, and table top chains, among others. We have various types of fully automatic CNC production equipment, as well as fully automatic assembly equipment. Our products are of high quality, competitively priced, and come with excellent customer service. We welcome customization requests from our customers. For more information, please visit our website at https://table-top-chains.com.

Q&A

Q: How often should leaf chains be lubricated?

A: Leaf chains should be lubricated at least once a month or based on the machine usage and environment conditions.

Q: What kind of lubricant should be used for leaf chains?

A: It is recommended to use a high-quality, industrial-grade lubricant that is compatible with the chain material and application requirements.

Q: Can automatic lubrication systems be retrofitted to existing machines?

A: Yes, automatic lubrication systems can be retrofitted to existing machines, provided they are compatible with the machine's design and specifications.

Q: What are the benefits of using table top chains?

A: Table top chains are versatile and ideal for conveying a wide range of products in various industries, including food and beverage, automotive, and pharmaceuticals. They are easy to clean, require minimal maintenance, and offer quiet and smooth operation.

Q: How can I request customization of leaf chains?

A: You can contact our customer service team or visit our website for more information on customization requests.