How to Properly Document and Track Leaf Chain Wear Over Time

Leaf chains are an essential component of various industrial machines, including forklifts and cranes. Over time, these chains can experience wear and tear, which can lead to malfunctions and even accidents. It is therefore essential to document and track leaf chain wear over time to ensure optimal performance and prevent failures. In this article, we will discuss the steps required to properly document and track leaf chain wear over time.

What is Leaf Chain Wear?

Leaf chain wear refers to the gradual loss of material from the chain's surface due to friction and stress. The wear can occur on the chain's pins, plates, and bushings, and it can cause the chain to stretch or even break. Therefore, it is crucial to monitor the chain's wear regularly and document any changes to ensure its optimal performance and safety.

Tools Required for Documenting and Tracking Leaf Chain Wear

Before we discuss the steps required to document and track leaf chain wear, let's first look at the tools required. These include:

- Caliper or micrometer

- Chain wear gauge

- Measuring tape

- Pen and paper or computer spreadsheet

Step-by-Step Guide for Documenting and Tracking Leaf Chain Wear

Step 1: Measure the Chain Length

The first step in documenting and tracking leaf chain wear is to measure the chain's length. Use a measuring tape to measure the overall length of the chain, including any attachments or hooks. Record the measurement in a spreadsheet or on paper.

Step 2: Measure the Chain Pitch

The next step is to measure the chain's pitch, which is the distance between the centers of two adjacent pins. You can use a caliper or micrometer to measure the pitch accurately. Record the measurement in your spreadsheet or on paper.

Step 3: Measure the Pin Diameter

The pin diameter is the thickness of the chain's pins, which can also experience wear and tear. Use a micrometer to measure the pin thickness accurately. Record the measurement in your spreadsheet or on paper.

Step 4: Measure Chain Elongation

Chain elongation is the stretching of the chain over time due to wear and tear. You can use a chain wear gauge to measure the elongation accurately. Place the gauge on the chain and check the measurement. Record the measurement in your spreadsheet or on paper.

Step 5: Compare with the Manufacturer's Specifications

The final step is to compare your measurements with the manufacturer's specifications. Check the manufacturer's manual or website for the recommended chain length, pitch, pin diameter, and elongation. If your measurements fall outside of the recommended specifications, it may be time to replace the chain.

Using Table Top Chains for Better Performance

If you are looking for a reliable and durable chain alternative, consider using table top chains. Table top chains are made of high-quality materials and are designed to withstand heavy loads and high speeds. They also offer superior wear resistance and require less maintenance than traditional leaf chains. For more information on table top chains, visit https://table-top-chains.com.

Company Introduction and Product Promotion

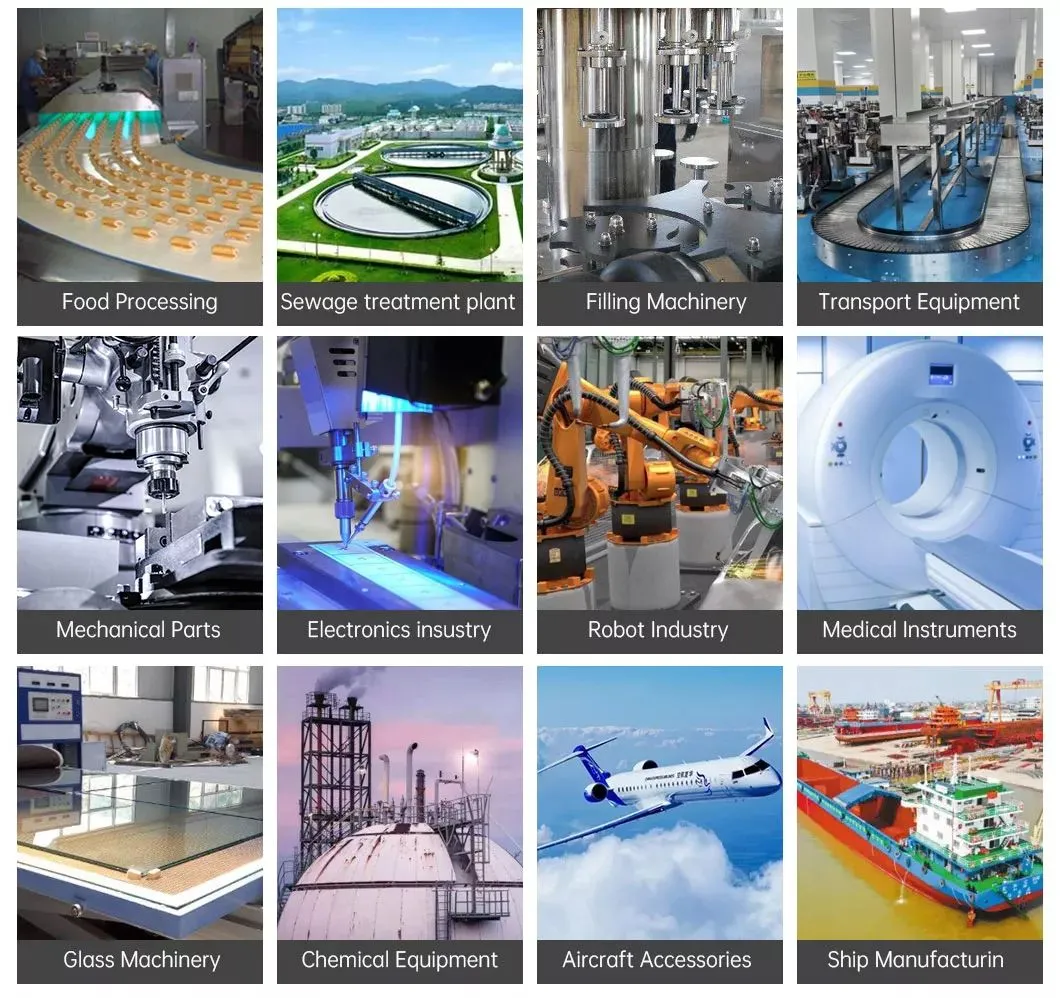

At our company, we are a leading player in the Chinese chain market. Our products include leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, and table top chains. We have various types of fully automatic CNC production equipment and automatic assembly equipment. Our products are of high-quality and are available at competitive prices. We also offer customized solutions to meet our customers' needs. See our products on https://leaf-chains.net/.

Q&A

Q1: How often should I document and track leaf chain wear?

A1: It is recommended to document and track leaf chain wear every 500 hours of operation or every three months, whichever comes first.

Q2: Can I use a ruler to measure the chain length?

A2: It is not recommended to use a ruler to measure the chain length as it may not be accurate enough. A measuring tape or digital caliper is a better option.

Q3: Is it possible to repair a worn-out leaf chain?

A3: In most cases, it is not recommended to repair a worn-out leaf chain as it may cause more harm than good. It is best to replace the chain with a new one.

Q4: What are the signs of leaf chain wear?

A4: Signs of leaf chain wear include elongation, chain slippage, chain noise, and visible signs of wear on the pins and plates.

Q5: How can I extend the life of my leaf chain?

A5: To extend the life of your leaf chain, ensure that it is properly lubricated, regularly cleaned, and not exposed to excessive loads or speeds.