Estimating Leaf Chain Lifespan for Budgeting

Leaf chains are used in a wide range of industrial applications, from forklifts to cranes to hoists. They provide reliable and efficient power transmission, but like all mechanical components, they have a limited lifespan. In this article, we will discuss how to estimate the lifespan of leaf chains, and how to budget for their replacement.

What is a Leaf Chain?

A leaf chain is a type of roller chain that is designed to handle heavy loads and provide accurate positioning. It consists of a series of link plates and pins that are held together by steel tubes called “barrel rollers”. The rollers allow the chain to roll smoothly over sprockets, while the link plates transmit power from one end of the chain to the other.

Factors Affecting Leaf Chain Lifespan

The lifespan of a leaf chain depends on a variety of factors, including:

- Load capacity: The amount of weight the chain is designed to carry

- Speed: The rate at which the chain moves

- Temperature: The operating temperature of the chain and its environment

- Maintenance: The frequency and quality of maintenance performed on the chain

How to Estimate Leaf Chain Lifespan

Estimating the lifespan of a leaf chain can be challenging, as it depends on so many factors. However, there are some general guidelines you can follow:

- Consult the manufacturer's specifications: The manufacturer should provide information on the expected lifespan of the chain under various operating conditions.

- Perform regular inspections: Look for signs of wear, such as elongation, and replace the chain before it fails.

- Monitor operating conditions: Keep track of the load, speed, and temperature of the chain, and adjust maintenance schedules as needed.

How to Budget for Leaf Chain Replacement

Leaf chain replacement can be a significant expense, especially if you have multiple machines that use leaf chains. To budget for replacement, you should consider:

- The expected lifespan of the chain

- The number of machines that use leaf chains

- The cost of replacement chains

- The cost of labor to install the chains

By estimating the lifespan of your leaf chains and budgeting for their replacement, you can avoid unexpected downtime and keep your equipment running smoothly.

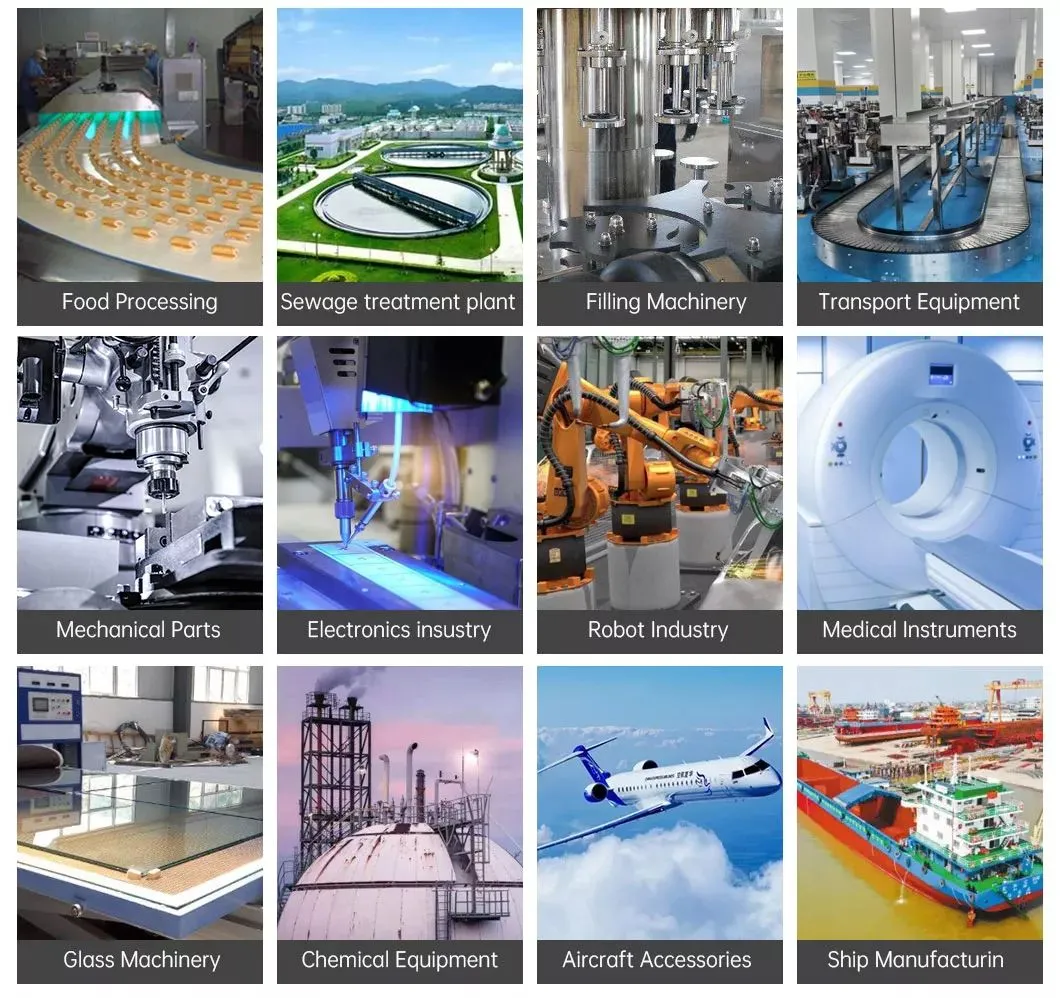

Using Leaf Chains in Applications

Leaf chains are versatile components that can be used in a wide range of industrial applications. They are commonly used in forklifts, cranes, hoists, and other lifting devices. They are also used in conveyors, packaging equipment, and other machinery that requires accurate positioning and high load capacity.

About Our Company

Our company is a leader in the Chinese chain market, offering a wide range of products including leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, and table top chains. We have a variety of fully automated CNC production equipment, as well as automatic assembly equipment, to ensure the highest level of quality and efficiency.

We take pride in our products, which are designed to meet the highest standards of quality and durability. We offer competitive prices and excellent customer service, and we welcome custom orders for all of our products. To learn more about our products, please visit our website at https://table-top-chains.com.

Factory Image

Q&A

Q: What is the load capacity of a typical leaf chain?

A: The load capacity of a leaf chain can vary depending on the size and design of the chain. However, most leaf chains are designed to handle loads ranging from a few hundred pounds to several thousand pounds.

Q: What is the operating temperature range for a leaf chain?

A: The operating temperature range for a leaf chain can vary depending on the materials used in its construction. However, most leaf chains are designed to operate within a temperature range of -40¡ãC to 150¡ãC.

Q: How often should I inspect my leaf chain for wear?

A: It is recommended to inspect your leaf chain at least once a month for signs of wear, such as elongation. However, the frequency of inspections may need to be adjusted based on the operating conditions of the chain.

Q: Can I replace a single leaf chain link if it is damaged?

A: In most cases, it is not recommended to replace a single link in a leaf chain. This can disrupt the balance of the chain and lead to premature wear or failure. It is generally better to replace the entire chain.

Q: How long does it take to replace a leaf chain?

A: The time required to replace a leaf chain can vary depending on the size and complexity of the machine. In general, it can take several hours to replace a leaf chain, including time for disassembly, installation, and adjustment.