Eco-friendly Materials in Leaf Chain Production

Leaf chains are an essential component in many industries, including construction, agriculture, and automotive. Traditionally, these chains have been manufactured using materials that have a negative impact on the environment. However, with the rise of eco-consciousness, manufacturers are exploring alternative materials that are both sustainable and durable. In this article, we will explore the use of eco-friendly materials in leaf chain production, their benefits, and how they contribute to a greener environment.

The Need for Eco-Friendly Materials in Leaf Chain Production

The manufacturing process of traditional leaf chains involves the use of materials such as steel, which is not biodegradable and has a high carbon footprint. The production process also requires a considerable amount of energy, which results in significant greenhouse gas emissions. This has led to an increased demand for eco-friendly materials that can replace traditional materials in leaf chain production.

Bio-Based Plastics

Bio-based plastics are a promising alternative to traditional materials used in leaf chain production. These materials are derived from renewable sources such as corn, sugarcane, or potato starch. Bio-based plastics have several advantages over traditional materials, including lower carbon footprint, biodegradability, and a reduced dependency on fossil fuels. These materials are also lightweight and have high-strength properties, making them ideal for use in leaf chain production.

Recycled Materials

Recycled materials such as steel and aluminum can also be used in leaf chain production. The use of recycled materials reduces the carbon footprint of the manufacturing process and helps to conserve natural resources. Recycled materials can be used to produce high-quality leaf chains that are both durable and sustainable.

Bamboo

Bamboo is another eco-friendly material that can be used in leaf chain production. Bamboo is a rapidly renewable resource that grows much faster than traditional trees. It is also biodegradable and has a high-strength to weight ratio. Using bamboo in leaf chain production reduces the carbon footprint of the manufacturing process and contributes to a greener environment.

Benefits of Using Eco-Friendly Materials in Leaf Chain Production

The use of eco-friendly materials in leaf chain production has several benefits:

- Reduced carbon footprint

- Conserves natural resources

- Biodegradability

- Reduced dependency on fossil fuels

- Lower manufacturing costs

- Improved brand reputation

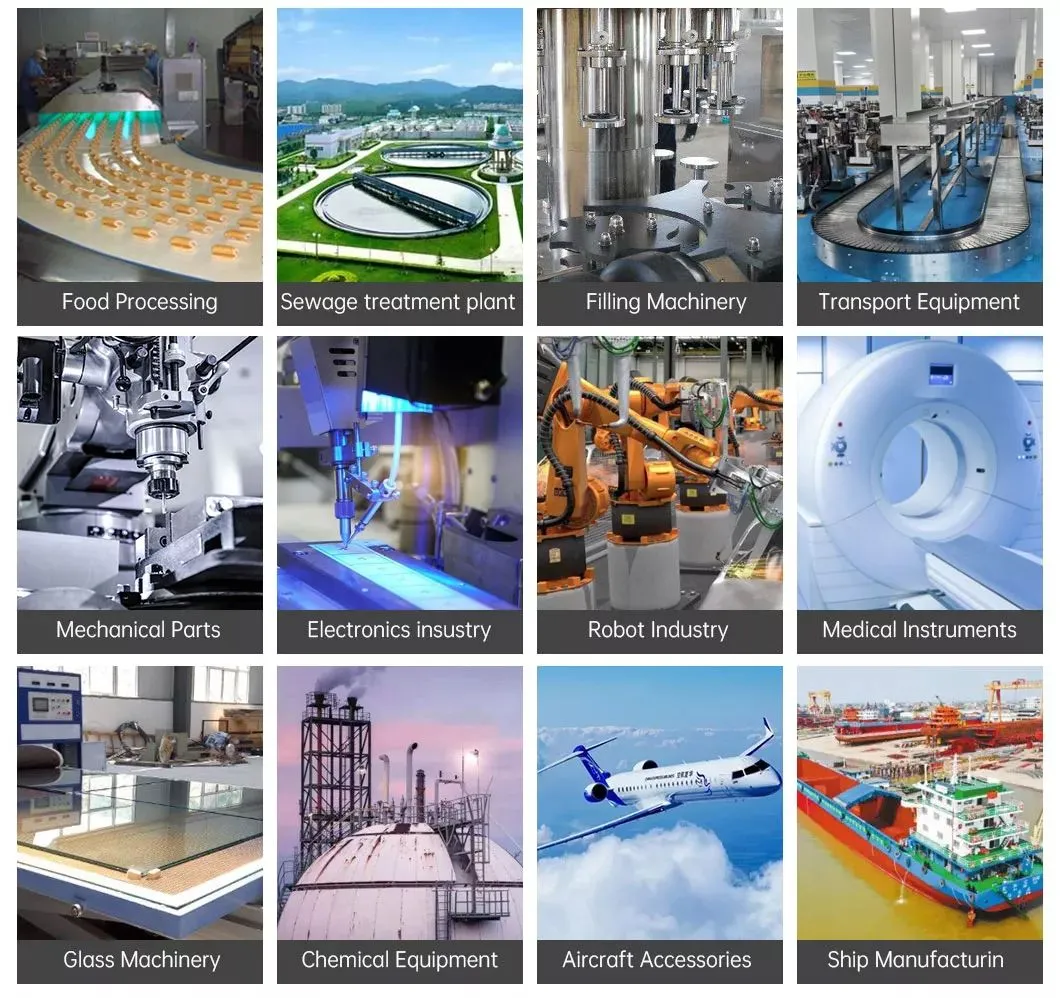

Application and Usage

Eco-friendly leaf chains can be used in a wide range of applications, including construction equipment, agricultural machinery, and automotive systems. These chains are durable, reliable, and sustainable, making them an excellent choice for companies looking to reduce their carbon footprint and contribute to a greener environment.

Table top chains are one of the most widely used types of chains in the industry. If you are interested in exploring more about table top chains, please visit https://table-top-chains.com.

Company Promotion and Introduction

Our company is a leading player in the Chinese chain market. We specialize in the production of leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, conveyor chains, and table top chains. Our state-of-the-art, fully automated production and assembly equipment ensure that we deliver high-quality products at competitive prices. We welcome custom orders from our customers, and we pride ourselves on providing exceptional service to our clients.

Q&A

Q: Are eco-friendly leaf chains as durable as traditional leaf chains?

A: Yes, eco-friendly leaf chains are just as durable as traditional leaf chains, and in some cases, they can be even more durable.

Q: Can eco-friendly leaf chains be used in heavy-duty applications?

A: Yes, eco-friendly leaf chains can be used in heavy-duty applications. They have high-strength properties and can withstand heavy loads.

Q: Are there any disadvantages to using eco-friendly materials in leaf chain production?

A: One disadvantage of using eco-friendly materials is that they can be more expensive than traditional materials. However, the long-term benefits, such as reduced carbon footprint and improved brand reputation, far outweigh the initial costs.

Q: Can recycled materials be used to produce high-quality leaf chains?

A: Yes, recycled materials such as steel and aluminum can be used to produce high-quality leaf chains that are both durable and sustainable.

Q: How can companies benefit from using eco-friendly leaf chains?

A: Companies that use eco-friendly leaf chains can benefit from improved brand reputation, reduced carbon footprint, and lower manufacturing costs.