Custom Leaf Chain Designs for Complex Lifting Mechanisms

Leaf chains are a type of rollerless chain that are commonly used in lifting mechanisms. They consist of interlocking links that are joined together to form a flexible and durable chain. Leaf chains are ideal for use in applications where high strength and long service life are required. They are used in a wide range of lifting equipment, including forklifts, cranes, and hoists.

The Importance of Custom Leaf Chain Designs

Standard leaf chains are available in a range of sizes and configurations, but they may not always be suitable for complex lifting mechanisms. Custom leaf chain designs can provide a solution to this problem. By tailoring the design of the chain to the specific needs of the application, it is possible to achieve a more efficient and effective lifting mechanism.

Factors to Consider in Custom Leaf Chain Design

When designing a custom leaf chain, there are several factors that must be taken into account:

- Load capacity

- Speed

- Environmental conditions

- Size and shape of the lifting mechanism

Load Capacity

The load capacity of the leaf chain is one of the most important considerations. The chain must be able to support the weight of the load without stretching or breaking. The load capacity of the chain can be increased by increasing the width or thickness of the links or by using a higher grade of steel.

Speed

The speed of the lifting mechanism is another important factor. The chain must be able to operate at the required speed without excessive wear or fatigue. The speed of the chain can be increased by reducing the weight of the links or by increasing the number of links in the chain.

Environmental Conditions

The environment in which the lifting mechanism operates can also have an impact on the design of the leaf chain. For example, if the chain is used in a corrosive or abrasive environment, it may be necessary to use a special coating or material to protect the chain from damage.

Application of Custom Leaf Chain Designs

Custom leaf chain designs can be used in a wide range of lifting applications. One example is in forklifts, where leaf chains are used to raise and lower the forks. Custom leaf chain designs can help to improve the performance and efficiency of forklifts, making them more effective in handling heavy loads.

Custom Leaf Chain Designs for Cranes

Custom leaf chain designs can also be used in cranes. Cranes are used to lift heavy loads in construction and manufacturing environments. Custom leaf chain designs can provide a more efficient and reliable lifting mechanism for cranes.

Custom Leaf Chain Designs for Hoists

Hoists are another application where custom leaf chain designs can be used. Hoists are used to lift and lower loads in a range of industrial and commercial settings. Custom leaf chain designs can help to improve the safety and efficiency of hoists, making them more reliable and effective.

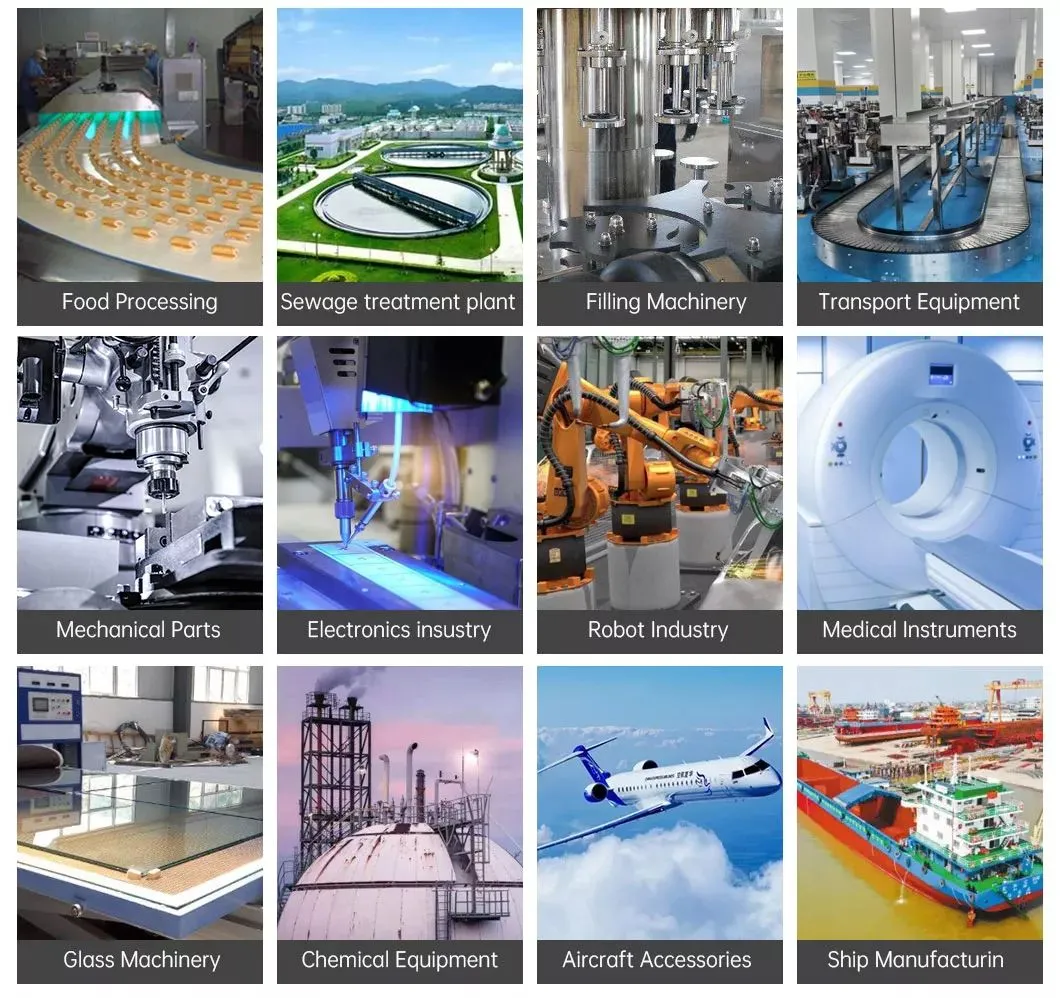

Company Products and Services

Our company is a leading supplier of leaf chains, cotter type chains, conveyor chains, bush chains, double flex chains, sprocket chains, and table top chains in the Chinese market. We have a wide range of fully automatic CNC production equipment, as well as automatic assembly equipment. We offer high-quality products, competitive prices, and excellent customer service. We welcome customers to provide us with drawings or samples for custom chain designs.

Please visit our website for more information on our products and services. If you are interested in our table top chains, please click here to learn more.

Q&A

Q: What is the load capacity of a leaf chain?

A: The load capacity of a leaf chain depends on several factors, including the size and thickness of the links, the grade of steel used, and the environmental conditions in which the chain operates. Custom leaf chain designs can be tailored to meet the specific load requirements of an application.

Q: What kind of coating can be used to protect a leaf chain in a corrosive environment?

A: There are several coatings that can be used to protect a leaf chain in a corrosive environment, including zinc plating, chrome plating, and nickel plating. The choice of coating will depend on the specific requirements of the application.

Q: How can custom leaf chain designs improve the performance of a forklift?

A: Custom leaf chain designs can improve the performance of a forklift by providing a more efficient and reliable lifting mechanism. By tailoring the design of the chain to the specific needs of the forklift, it is possible to achieve better load capacity, speed, and durability.

Q: What kind of lifting mechanisms can custom leaf chain designs be used in?

A: Custom leaf chain designs can be used in a wide range of lifting mechanisms, including forklifts, cranes, hoists, and other industrial equipment.

Q: What is the advantage of using table top chains?

A: Table top chains are ideal for use in applications where a flat surface is required for conveying items. They are commonly used in the food and beverage industry, as well as in packaging and manufacturing. The advantage of using table top chains is that they provide a smooth, flat surface that is easy to clean and maintain.

Q: What is the lead time for custom leaf chain designs?

A: The lead time for custom leaf chain designs will depend on the specific requirements of the application. Our company has a wide range of fully automatic CNC production equipment, as well as automatic assembly equipment, which allows us to provide fast and reliable service to our customers.